Setting A New Standard in Safety and Reliability: How Fortifyit Revolutionized IoT Device Manufacturing

Very partnered with Fortifyit set out on a journey to overcome the challenges of integrating sensitive accelerometers with robust ultrasonic welding with advanced IoT solutions that have set a new standard for reliability and safety.

FortifyIt (formerly Durasense)

Premier aftermarket IoT and digital platform solution for facility loading docks.

Teams Involved

Hardware Engineering, Product Design, Manufacturing Support

Project Duration

2 Years

Tech Stack

LoRaWAN, Bluetooth, Zephyr, KerOS (Linux), MQTT, Azure IoTHub, Docker

In the ever-evolving landscape of IoT, where innovation drives the industry, Fortifyit emerged with a bold vision: transform the maintenance and monitoring of loading dock equipment using cutting-edge IoT technology. Partnering with Very, a leader in IoT solutions, Fortifyit set out on a journey to overcome the challenges of integrating sensitive accelerometers with robust ultrasonic welding.

Fortify System Device Renderings

The Client

DuraServ, the market leader in bay doors and loading dock equipment, established the Fortifyit venture to develop a pioneering IoT and digital platform solution. Their aim was to transform how businesses monitor and manage the health of their assets remotely, providing crucial operational insights. Ultimately enabling an evolution from reactive maintenance to preventive maintenance backed by predictive analytics.

The Challenge: A Technical Hurdle

The challenge faced by Nick Petersen, Director at FortifyIt, was evident: How could they transform not just how they respond to equipment failures, but create a way to better anticipate them? The journey was not without its hurdles. As Fortifyit transitioned from adhesive bonding to ultrasonic welding to improve the durability of their IoT devices, they encountered a significant obstacle. The high-frequency vibrations from the welding process were causing the accelerometers—critical for monitoring equipment integrity—to malfunction, leading to erroneous readings and calibration failures, which critically impacted the device’s ability to monitor and report accurately on the operational integrity of overhead metal doors and dock levelers.

Ultrasonic welding, when applied to the assembly of delicate components like those in a 6-axis IMU and gyroscopic sensors, demands a nuanced understanding of material science and mechanical engineering. The challenge lies in applying just enough energy to create a robust bond without compromising the integrity of sensitive micro-electromechanical systems.

Our approach involves precise calibration of the welding parameters—adjusting the amplitude, pressure, and duration—to ensure that the thermal and mechanical stresses do not affect the sensor’s alignment and performance. This level of precision ensures that the functionality of our IMU and gyroscopic sensors remains optimal in all operating conditions, which is crucial for maintaining the accuracy and reliability of the device’s motion tracking capabilities.

Heath Marvin, SVP Engineering, Very

Unraveling the Mystery of Malfunctioning Accelerometers to Create a Powerful Solution

Faced with malfunctioning accelerometers, the team embarked on a meticulous investigation. The challenge was to pinpoint the exact cause of the problem and find a solution that would not compromise the device’s performance or the durability gains from ultrasonic welding.

Through collaborative efforts and technical ingenuity, Very’s team explored various solutions, including adjusting the ultrasonic welding parameters and testing different accelerometer placements. It was a process of trial and error, backed by data-driven insights and strategic revisions.

Solution

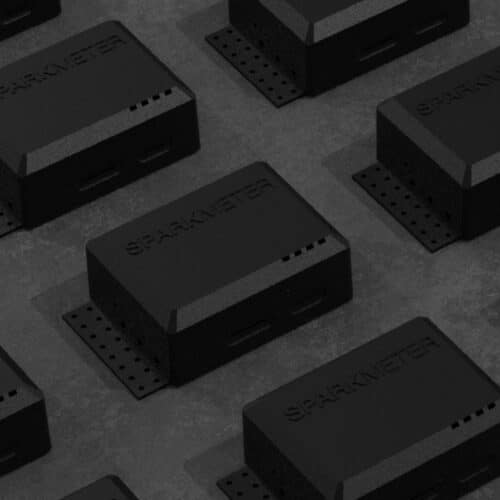

Fortify Sensor Node Enclosures

→ Fortifyit developed custom modular sensor nodes to track usage of doors and dock levelers

→ Sensor nodes transmit data over a LoRaWAN network to a Linux gateway, which then uploads the data to Azure IoT Hub

→ Advanced machine learning algorithms were employed to generate unique operational signatures for each asset, enabling the early detection of anomalies that could indicate impending equipment failure

→ Extreme service life necessitated that these algorithms run directly on the sensors, minimizing data transmission, and maximizing battery longevity

Nick Petersen, Director, FortifyitLaunching Fortifyit was about transforming not just how we respond to equipment failures, but how we anticipate them. Our collaboration with Very was pivotal; they understood the critical nature of our industry’s needs. Together, we created a robust IoT solution that not only predicts failures but actively prevents them, drastically reducing downtime and ensuring safety. This project was not just about technological innovation; it was about crafting a solution that could save lives and significantly enhance operational efficiency. The journey from a conceptual proof of idea to a scalable solution was marked by rigorous testing, refinement, and a deep commitment to excellence that Very brought to the table.

Now, as we look ahead, we’re poised not only to expand this technology to over 30,000 assets but also to explore new applications that could benefit from our pioneering approach.

The Outcome

Fortify Device Rendering

A New Era of Efficiency

Through its partnership with Very, Fortifyit now offers a comprehensive monitoring solution that delivers continuous insights from the dock to the boardroom, enabling proactive asset management and drastically reducing downtime and maintenance costs

The adjustments made to the ultrasonic welding process restored the accelerometers’ functionality, leading to reliable IoT devices that accurately monitored loading dock equipment. This success story not only resolved Fortifyit’s immediate technical challenges but also paved the way for future innovations in IoT manufacturing.

Beyond The Solution

Impact and Future Prospects

The impact of this project extends beyond technical success. Fortifyit strengthened its market position, offering advanced IoT solutions that set new standards for reliability and safety. Looking ahead, the company plans to expand its IoT solutions into new markets, driven by the insights and strategies developed in collaboration with Very.

The Fortifyit case study offers valuable lessons in IoT device manufacturing:

→ Iterative Testing and Feedback Loops: Importance of continuous testing and adjustments.

→ Cross-Disciplinary Collaboration: Leveraging expertise from various fields to drive innovation.

→ Strategic Risk Management: Proactively identifying and mitigating risks in complex projects.

The Fortifyit project exemplifies the power of collaboration and innovation in overcoming technical challenges. By turning obstacles into opportunities, Fortifyit and Very have set a benchmark for excellence in IoT manufacturing.

If you have an IoT project on the horizon or want to learn more about how we’re transforming how companies leverage their device data to solve real-world problems, feel free to book a meeting with our team.

Let's talk about your vision for a powerful IoT solution.