BLOG

Unlock the Full Potential of Your Devices with Custom PCBs

Investing in custom printed circuit boards (PCBs) is more than just a technical decision – it’s also a strategic one, as custom PCBs provide a tailored approach that can significantly enhance both your product as well as your company’s competitive position.

Meeting Your Specific Performance Criteria

Custom PCBs are designed to meet specific performance criteria that generic boards can’t always fulfill. If you consider high-end applications in sectors like aerospace, healthcare, and advanced consumer electronics, custom PCBs are necessary to allow for specialized components and functionalities. This customization ensures optimal performance and reliability, which is especially crucial where failure isn’t an option.

Worth the Long-Term Financial Benefits

It’s true, the initial investment in custom PCB design upfront can be higher than if you were to purchase standard, off-the-shelf boards. However, the long-term financial benefits are compelling. Custom PCBs can be optimized for more efficient production and assembly processes, leading to lower overall manufacturing costs. What’s more, a board specifically designed for your application can reduce the need for future modifications and provide easier scalability, thus avoiding the often hidden costs associated with adapting off-the-shelf solutions to fit non-standard requirements.

Protecting Your Intellectual Property

We all know how competitive the tech industry can be, which is why protecting your intellectual property (IP) can be as important as creating innovative products. Custom PCBs offer the opportunity to develop proprietary technology that can be patented, giving you a competitive edge and potentially opening additional revenue streams through licensing. This is a strategic advantage that’s often overlooked but should definitely be taken into consideration as it safeguards your company’s innovations and strengthens your foothold in the marketplace.

Enhancing Supply Chain Efficiency

If you’re looking to simplify your supply chain by reducing the number of necessary vendors and parts then custom PCB development is a viable option. This streamlining can lead to significant reductions in logistics costs and decrease the complexity of supply chain management. Moreover, closer collaboration with a PCB manufacturer can ensure quicker response times and more flexible production adjustments, enhancing overall efficiency.

Standing Out in a Crowded Market

The marketplace today is saturated with similar technologies, which means product differentiation has become even more important in capturing and retaining consumer interest. Custom PCB design can be highly innovative and distinguish your products from your competitors’. Whether it’s a slimmer profile, unique capabilities, or superior performance, a custom PCB can be the defining feature that sets your product apart.

A Hypothetical Use Case for Custom PCBs

According to the National Institutes of Health (NIH), approximately one in three Americans use a wearable health monitoring device to track their health and fitness.

Our fictional startup in the medical technology industry is focused on developing an innovative wearable device intended for continuous monitoring of patients with chronic conditions. This device aims to track vital health metrics like blood pressure, heart rate, and body temperature.

Not only does this device need to be lightweight, comfortable, and capable of integrating multiple sensors for accurate monitoring, it must also meet rigorous medical standards. Given this criteria, standard off-the-shelf PCBs aren’t able to meet all the specific requirements (size, power efficiency, and sensor integration) needed for this specialized application.

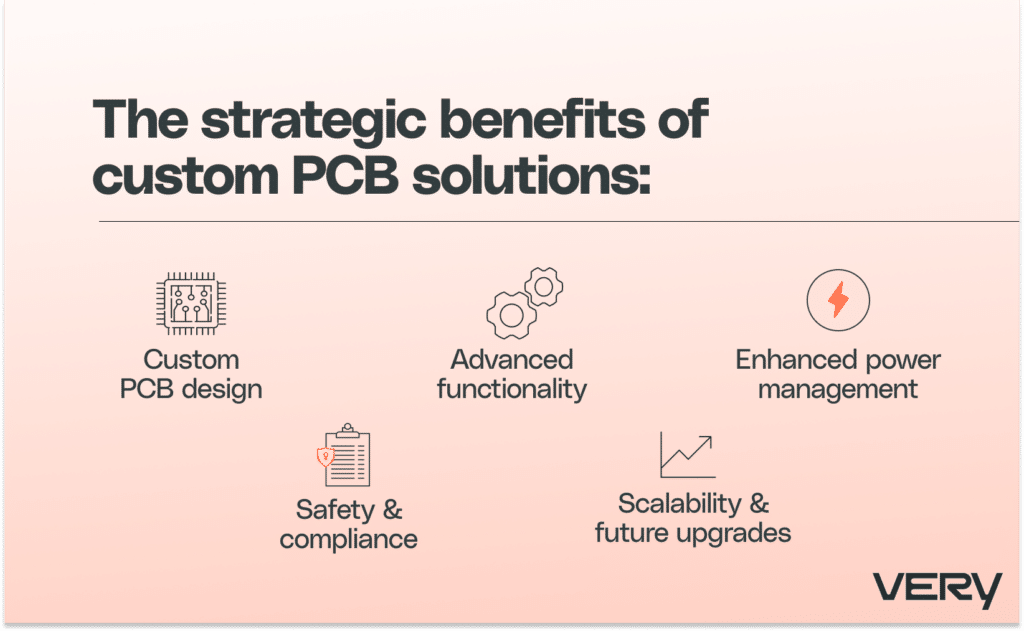

The startup decides to go with a custom PCB solution for several strategic reasons:

- Custom design: The custom PCB is meticulously designed to fit within the compact form of the wearable device, allowing for the integration of the necessary sensors in a user-friendly design without compromising functionality.

- Advanced functionality: Using a custom PCB makes it easier to implement a sophisticated algorithm for real-time data processing and anomaly detection, a critical requirement for immediate medical response.

- Enhanced power management: With custom PCBs, the startup is able to incorporate superior power management capabilities that extend battery life. This is essential for devices that are meant to be worn continuously without frequent recharging.

- Safety and compliance: Materials and components used for the custom PCB comply with medical safety standards, ensuring the device is safe for continuous skin contact and long-term use by patients.

- Scalability and future upgrades: The custom PCB design is scalable, allowing for easy adjustments and updates to the device’s features based on customer feedback and technological advancements without a complete overhaul.

The result? A wearable device that becomes known for its precision, reliability, and user-centric design. Custom PCB design enables the device to exceed market standards and user expectations, elevating user satisfaction and profitability due to the differentiation and the high performance of the product.

Does Custom PCB Development Align With Your Overall Business Objectives?

As you weigh the pros and cons of custom versus off-the-shelf PCBs, consider how taking a more tailored approach aligns with your broader business objectives related to cost efficiency, market differentiation, and IP protection.

At the end of the day, the decision to go custom could be a critical step in securing a future where your products lead the market, driven by innovation that’s both advanced and strategically sound.